Tree cabling helps support weak unions, reduce movement, and manage risk in compromised canopies. A reliable system depends on choosing the right termination hardware, using the correct splice method for the strand you are working with, and having the right installation tools on hand. This guide walks through a practical, professional setup using proven components available from Western Tree Equipment & Repairs.

Start With The Right Strand & Hardware Plan

Before selecting hardware, confirm the strand type and size for the job. Many professional tree cabling systems use 7-strand EHS cable, and the termination method should match the cable diameter and the style of installation.

A clean way to approach your setup is:

- Choose a termination style that fits your strand size and install preference

- Use a thimble or dead-end system as required

- Select a termination method that is compatible with EHS strand

- Keep an install tool ready so field work stays efficient

Tree Cabling Terminations (Wire Stops & Wedge-Style Options)

Rigguy Wire Stop for 3/8″ and 5/16″ EHS Strand

The Rigguy Wire Stop is a compact termination that uses a block and internal taper design. The taper fits over the center strand while the surrounding strands seat around it. As load increases, the taper seats deeper, increasing grip.

Rigguy Wire Stop for 1/4″ and 3/16″ EHS Strand

Rigguy Wire Stops are also available for smaller EHS sizes. The 1/4″ and 3/16″ Wire Stop uses the same tapered-grip concept in a size range suited for lighter applications.

Rigguy Wire Stop Taper Only Options

If you are replacing components or building out your system, Western carries taper-only options in both size ranges:

Using the correct taper for the correct Wire Stop size helps keep your termination consistent and reliable.

Preformed Line Products WEDGE-GRIP™ Dead-end

The WEDGE-GRIP Dead-end is a termination option for EHS and Common Grade strand that is designed to save time and labor. It uses a housing and wedge assembly that slides onto the strand, then secures when the cap is tightened. Western notes that it eliminates the need to twist strand or alter its integrity, and it is designed to maintain the strand’s published rated breaking strength.

Splices & Dead-Ends

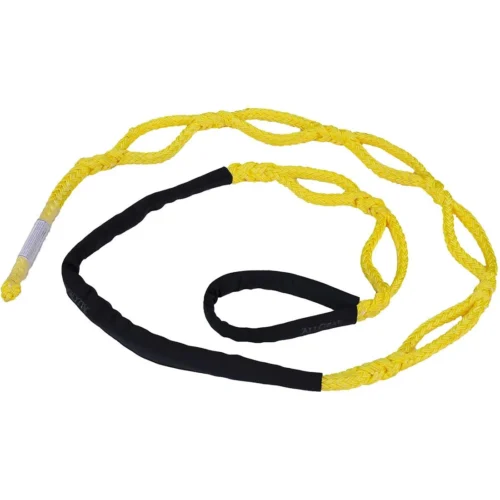

Preformed Tree Grip Dead End Guy Splice

EHS strand is not designed to be hand spliced. For static cabling applications, a Preformed Tree Grip Dead End Guy Splice provides a practical solution for creating an eye when paired with the correctly sized thimble. Western carries multiple sizes with color-coding to help identify the correct application:

- 3/16″ Red

- 1/4″ Yellow

- 5/16″ Black

- 3/8″ Orange

Install Tools That Make Cabling Faster & Cleaner

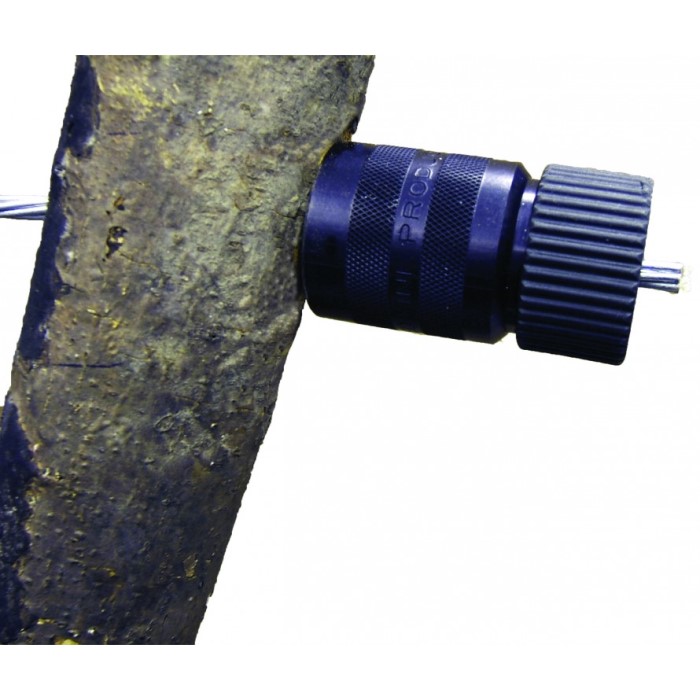

Preformed Line Products Tree Cabling Tool (Lag Spinner)

The right tools can make a big difference on cabling jobs. The Preformed Line Products Tree Cabling Tool, often called a lag spinner, is designed to help drive lag screws into wood during cabling installs. Western also notes it is built to work with PLP TREE-GRIP dead-ends and is made from solid aluminum.

Putting It Together For a Practical Cabling Setup

A simple workflow helps keep installs consistent:

- Confirm strand type and diameter.

- Choose terminations that match the strand size and job requirements.

- Use compatible dead-ends for creating eyes on EHS strand.

- Bring the right tool for lag installation and quicker field setup.

Shop Tree Cabling Hardware At Western Tree Equipment & Repairs

A solid cabling setup depends on compatible components, correct sizing, and reliable installation tools. Western Tree Equipment & Repairs carries professional-grade cabling and bracing hardware so you can build clean terminations and complete installs efficiently.